Bainite offer state of art customized and fully automated batch-off units to suit customer requirements. Our Batch-off units are popular for effective cooling & top-class stacking presentation which comprises of:

Take Away Conveyor

Stock Printer

Splicing Units

Dip Tanks

Festooner

Wig Wag unit

Special Features

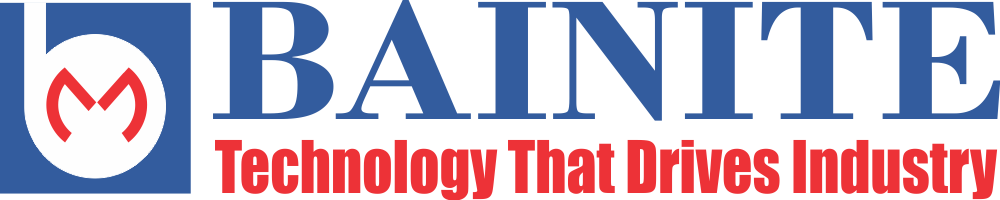

Auto pick up unit consists of moving trolley arrangement equipped with long and short pneumatically operated jaw mechanism including lowering and lifting up of mechanisms by pneumatic system. The unit is positively driven on the rails to & fro through chain sprocket mechanism. Suitable photo sensors are positioned for the smooth operation of auto pick up.

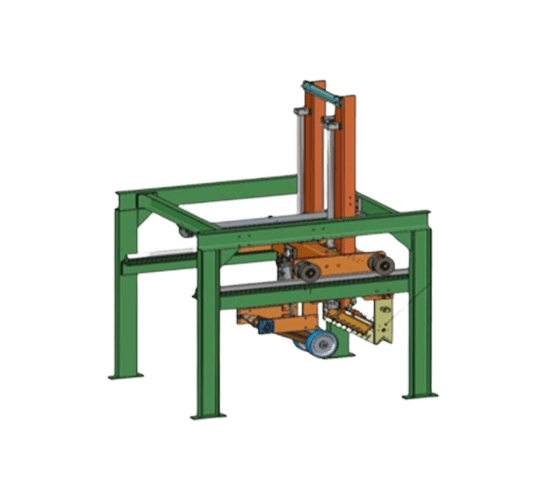

Auto packer stacker sheets slabs, or perforated strips are driven downward and stacked with precision on a pallet mounted on a lifted platform. On the supporting frame at both sides of the platform are positioned two pneumatically operated pressing plates. They are synchronized with the Wig-Wag festooner movement by detectors, and they are designed to alternatively push and keep the two stack edges pressed. This prevents the compound from moving or sliding and makes sure it is properly packed.

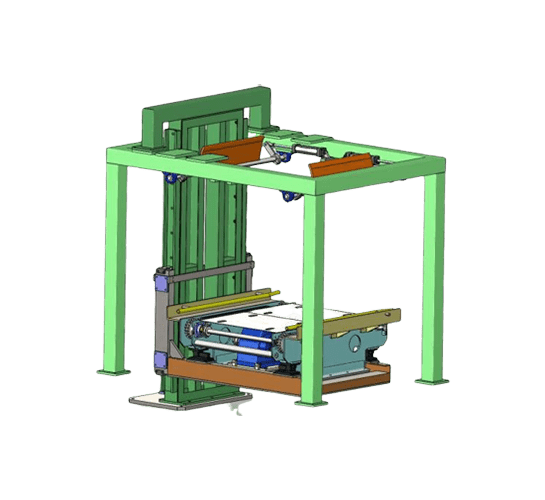

Auto palletizer assembly forwards the empty pallet to auto stacker assembly. This stores a stack of ~10 to 12 empty pallets enabled with lifting mechanism. This mechanism is adjusted in a way that it leaves the bottom most pallet on the platform and lifts the remaining pallets in the stack. The bottom most pallet is then passed on to the auto stacker. The lifting mechanism lowers pallet stack on the platform.

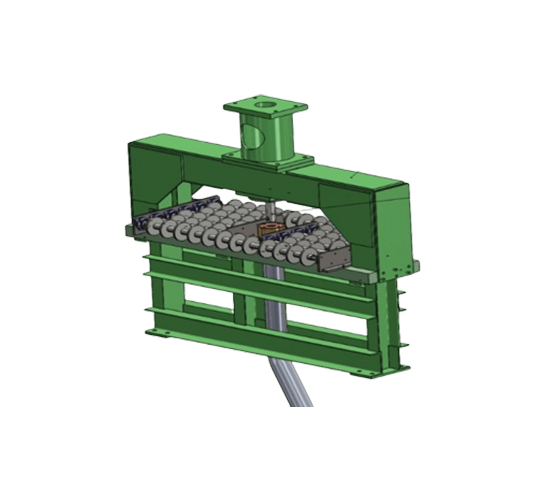

Auto-sampling unit is used to collect samples of rubber sheet for quality testing purpose. A sample is cut by means of a pneumatically operated cylinder with the help of die-punch assembly.

Sample piece is then sent for laboratory testing and remaining sheet is passed over to booking conveyor assembly.

Transport conveyor unit is used to transport the master batch sheet to first floor from ground floor batch-off unit. There is an additional wig wag unit at the end and can be used in conjunction with other options like Packer Stacker, auto-stacker etc.