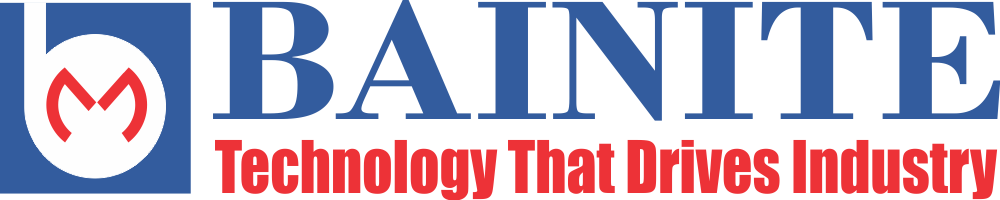

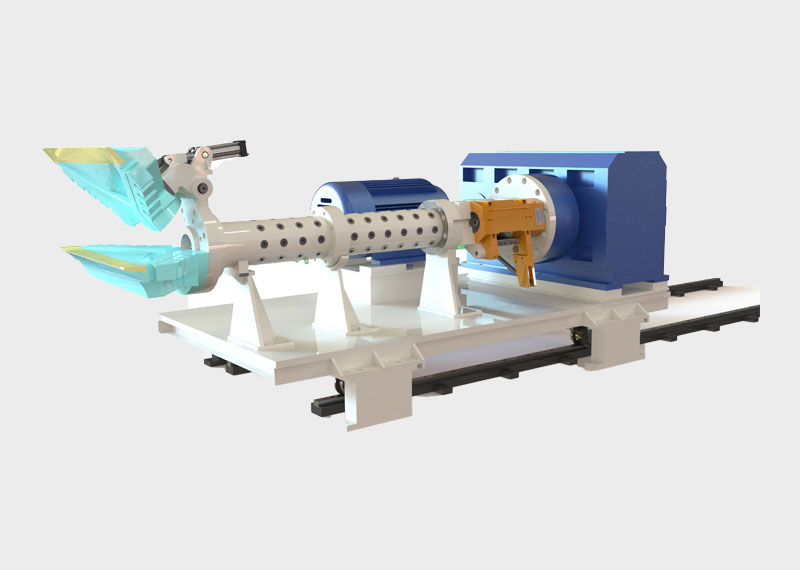

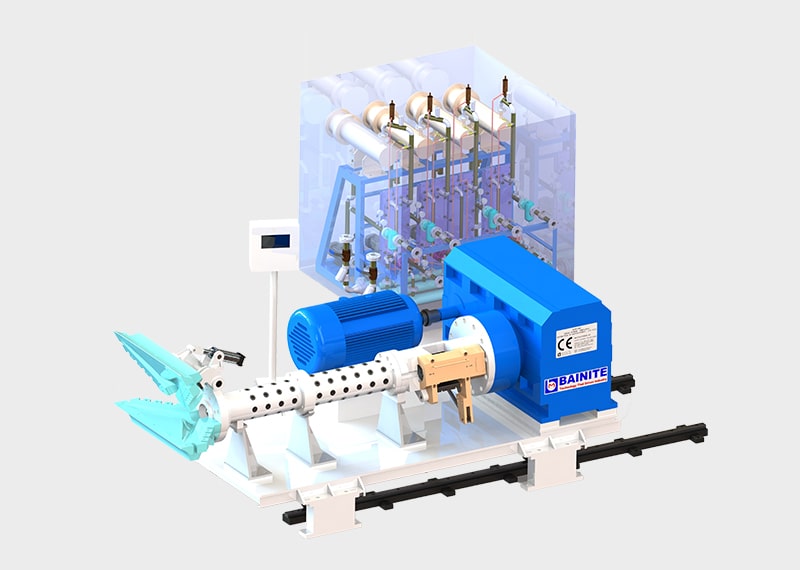

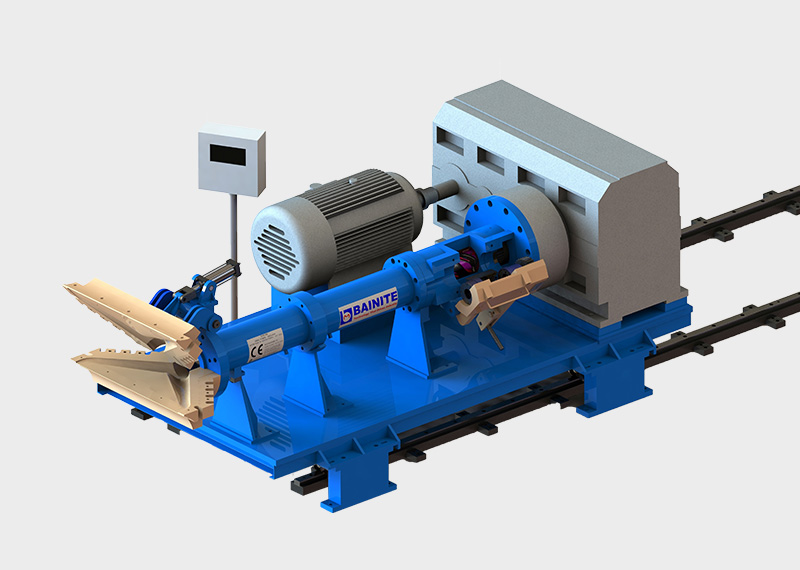

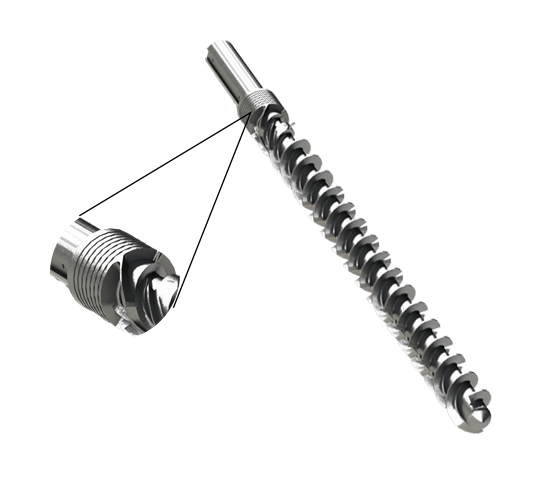

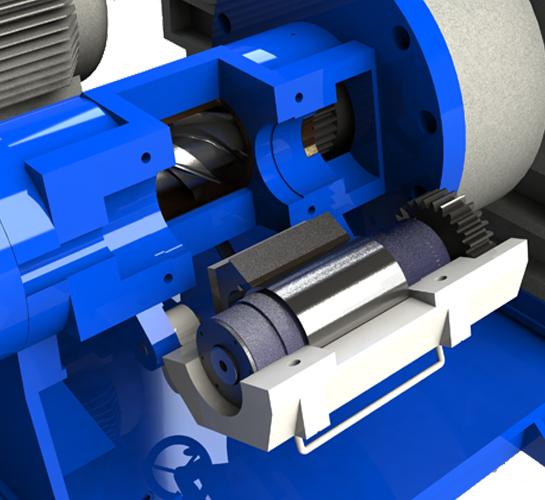

BM Series CFE are screw type rubber cold feed extruders popular in rubber processing industries for highest output, continuous mixing and consistent extrudate quality available with customised die head (like cross head, tube head, single or multiple tread heads, strainer head, or roller head) for your choice of application. Bainite offers duplex or triplex extruder for tire tread and side wall extrusion.

BM Series Cold Feed Extrudes are available in two variants:

- Pin Type

- Plain Type

Our CFEs are fast replacing 2 or 3 warming mill setup together with Hot feed extruder.