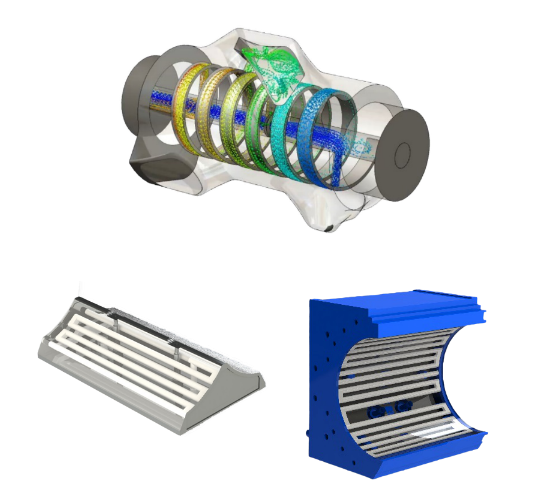

BM Series Intermeshing Mixers give enhanced dispersion and are widely preferred by non-tyre industries. They have spiral water-cooling design, which gives stable mixing by preventing rapid raise in temperature. Their rotors have unique interlocking mechanism, allowing maximum dispersion of ingredients and fillers within the batch. These Mixers are equipped with VFD (Variable friction drive) enabling the user to operate rotors at different speeds for various mixing scenario (Masters/Finals).

Key Features

Custom Built Mixers

High profile material science technology to combat increasing Silica usage

Special Coating on Rotors & Chambers for Increased lifespan

Dimensional Integrity ensures constant batch time for longer period of time

High Productivity - Enhanced Batch Weight & Batch Cycle

Rugged & Modern Design

Condition Monitoring- Dust Seals, Bearings & Lube System

Optimised Critical Parts Changing Methodology

Sophisticated Drive System – Gearbox lube oil temperature & Oil level monitoring, Motor Temperature sensing, Latest VFD system with PLC, HMI & SCADA, Recipe Management

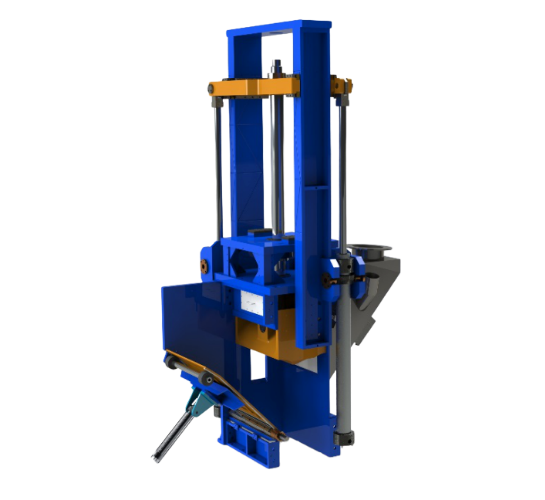

Discharge Door: Bainite offers hinged type “swing away” design operated by double rack and pinion arrangement. Broader Discharge Door to ensure quick Discharge & Zero Leakage

Complete Commissioning Service, Regular Audits , Spares Availability & Quick Response

Special Features

The parts of machine which come in contact with material are treated for wear resistance. Based on compound ingredients, MOC (Material of Content) & Special Wear Protective coatings will be formalized specially for high silica usage. This also ensures limited Carbon content. All the parts are machined on CNC for accuracy. They are ultrasonically, hydraulically, steam tested and stress relieved.

- Crack Free Rotor

Our SERVO controlled e-Hopper has a smart ram mechanism which offers automatic ram movement based on various mixing scenarios. It is capable to self-adjust speed, pressure and position based on the requirement.

The system is equipped with oil-less bushes and Large Feed Doors for rapid feeding. The design of the floating weight is enhanced to ensure maximum cooling. Additionally the system is equipped with dust extraction hood.

- Stock pressure can be varied in single batch

- Ram can be stopped at any position

- Variable positioning

- Fast Acting Ram with 3 Sec Up/ Down

- Sensing Stock pressure and automatically varying the RAM pressure accordingly

- All the above factors can be pre-programmed for different recipes

Bainite’s HP5 rotors are specially designed as two piece built. They are made with one long & two short nog design to enhance dispersion. Depending upon compound’s requirement, its main rotor body & end faces are surface treated. This ensures better performance & longevity.

- Crack Free Rotor

BM Series mixers will be equipped with leakage free SSA, BYH & Special Hydraulic dust stop system which offer Longer Trouble-Free Life & are easily replaceable.

- Superior Design Ensures Zero Leakage

- Available in Oil Less & Water-cooled design

Effective water-cooling channels are drilled across the Rotors, Drill sides, Floating weight, Dust stops, RE plates, & Drop Door for better temperature control.

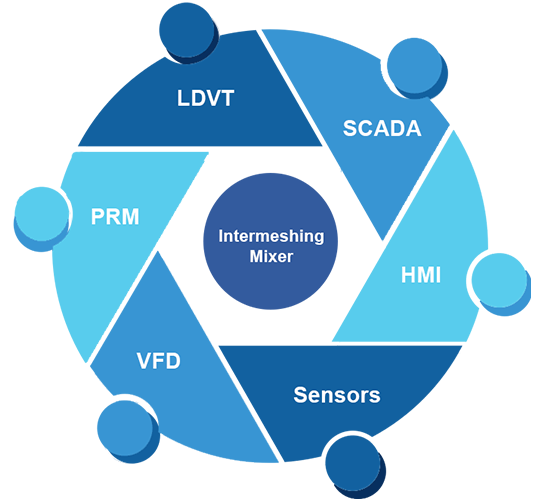

BM series mixers will be equipped with intelligent drive system featuring

- LVDT– Linear Variable Differential Transformer

- SCADA – Supervisory control and data acquisition

- HMI – Human-Machine Interface

- Sensors – Bearing, Compound & Oil temperatures and level sensors

- VFD – Variable Frequency Drive

- PRM – Programmable recipe management

| Model No. | RES-O-LAB | BMIM 25 | BMIM 50 | BMIM 95 | BMIM 150 | BMIM 210 | BMIM 330 |

|---|---|---|---|---|---|---|---|

| Volumes (In Litre) | 1.6 | 25 | 50 | 95 | 150 | 210 | 330 |

| Fill Factor | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Batch Weight @1.15 SG | 1.29 | 20 | 40 | 76 | 121 | 169 | 266 |

| Variable Rotor RPM | 12 to 120 | 6 to 60 | 6 to 60 | 6 to 60 | 6 to 60 | 6 to 60 | 6 to 60 |

| Rotor Type | HP5 | HP5 | HP5 | HP5 | HP5 | HP5 | HP5 |

| Motor Power ( in kW ) | 30 | 135 | 250 | 420 | 720 | 1100 | 1800 |

| Capacity ( ton / hr) | – | 0.36 | 0.72 | 1.38 | 2.17 | 3.04 | 4.78 |

(Note- Power Rating subejct to change as per media)

Safety Features