BM Series Hot Feed Extruders are popular in rubber processing industries for highest output, continuous mixing, and consistent extrudate quality. Suitable for applications like treads and sidewall, pelletizing, strainers, etc. Pre-heated rubber using cracker and warmer mill is fed into these extruders. A variant of this type is used as dump extruder below internal mixer in which screws are larger in diameter and a ram pusher is used for feeding dump.

Key Features

Liners are either Nitrided, case carburised or bimetallic in construction and is of wet design for efficient heat transfer.

Single base enables quick and effortless installation/ shifting/ relocation.

Customised Die Head with Hydraulic/ Pneumatic opening & closing.

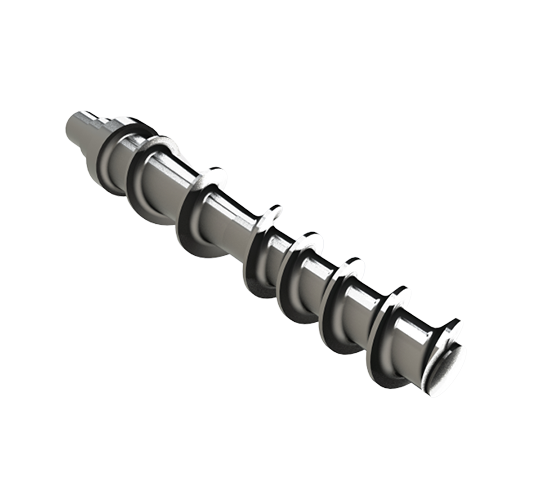

Different designs of screws are available to cater customised requirement with suitable wear protective Coatings.

Screws, made in alloy steel for better strength, screw is designed with sharp edges in the feed zone for homogenous mixing, and accurate throughput and porosity free compounds.

Solid barrels with spiral cuts at inner diameter also ensure efficient heat transfer.

Design and material technology of the die head is adopted to withstand ~700 bar max. pressure – eliminates any porosity, free of blisters or bubbles.

VFD Enabled

Available with Feed rack.

Pressure transducer on Head.

Screws completely heat-treated or stellited on the working surface for wear protection ensuring long-life, trouble -free and smooth running.

Effortless screw removal is possible manually without any hammering through a special tooling attachment that is supplied along with the extruder.

Special Features

BM series extruder heads will be equipped with pressure transduce and temperature monitoring and count systems. Bainite adopts latest flow simulation software to ensure that all die-heads are designed to have smooth flow of compound- spread in all directions under proper pressure and speed to eliminate any porosity. This ensures that the final extrudate product are free of blisters or bubbles.

BM Series Extruders will be equipped with customised heads like:

- Cross Heads

- Tread Head

- Pork Chop

- Strainer

- Strip

- Tube

- Roller Die

Bainite recognizes that with screw having a cantilever design, there is possibility of screw tip area scoring against the barrel inner surface, hence particular attention is given so that the thrust bearing housing in the gear reducer output assembly is designed to ensure concentric alignment with respect to barrel inner bore across the length of the screw.

Effortless screw removal is possible manually without any hammering through a special tooling attachment that is supplied along with the extruder.

| Model No | BM-HFE 3.5” | BM-HFE 4.5” | BM-HFE 6” | BM-HFE 8” | BM-HFE 10” | BM-HFE 12” |

|---|---|---|---|---|---|---|

| Screw Diameter | 90 | 120 | 150 | 200 | 250 | 300 |

| Screw Length (L/D) | 5 | 6 | 6 | 6 | 6 | 6 |

| Variable Screw RPM | 6 to 60 | 6 to 60 | 6 to 60 | 6 to 60 | 6 to 60 | 6 to 60 |

| Motor Rating ( kW ) | 40 | 60 | 75 | 150 | 210 | 280 |

| Capacity (ton / hr) | 0.3 | 0.75 | 1.2 | 2 | 3 | 4 |

| Head Profile | Customised | Customised | Customised | Customised | Customised | Customised |

(Note- Power Rating subject to change as per media)

Safety Features