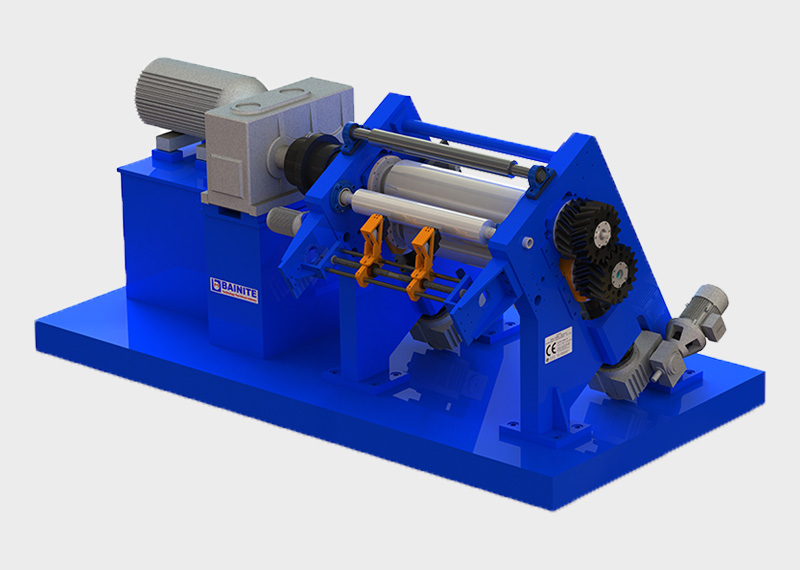

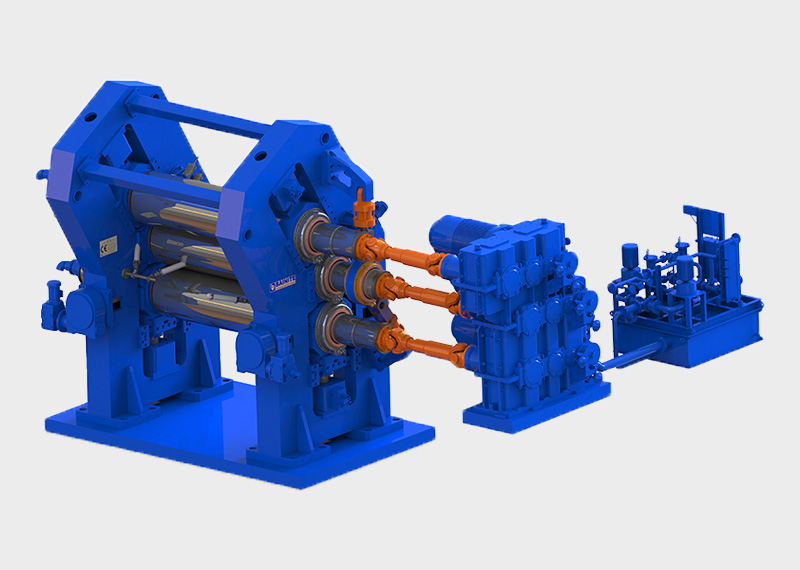

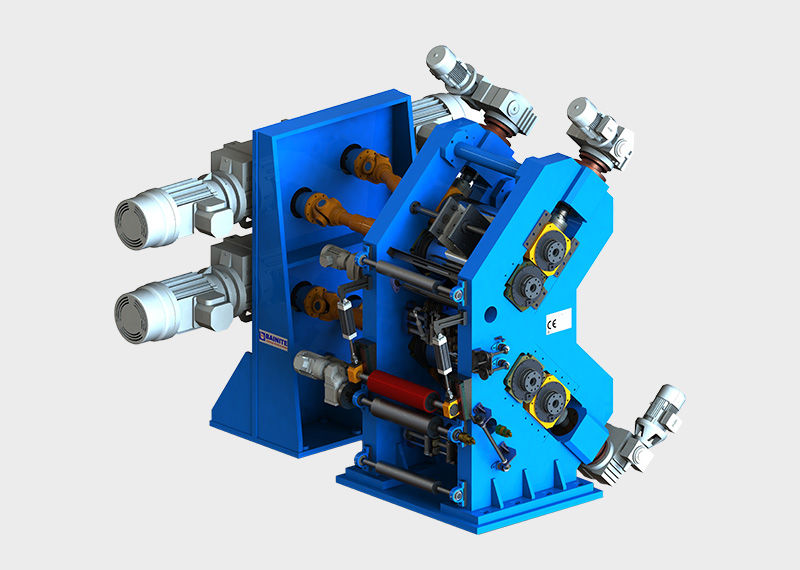

BM Series Calendar is specially designed for frictioning of fabrics single or double coating of fabrics and sheeting applications. They are custom-designed precision machines available with two, three or four roll configurations in different diameters and lengths, for rubber and plastic polymer industries.

Design parameters are determined by the type of product, specific gravity, PLI, widths, thickness, temperatures, accuracy, and productivity. Sophisticated Calenders with self-aligning roller bearings cross-axis or roll bending mechanism, preloaders, direct drives with motorized/Hydraulic nib adjustment and special peripherally drilled Cambered rolls, etc are offered for precision products.