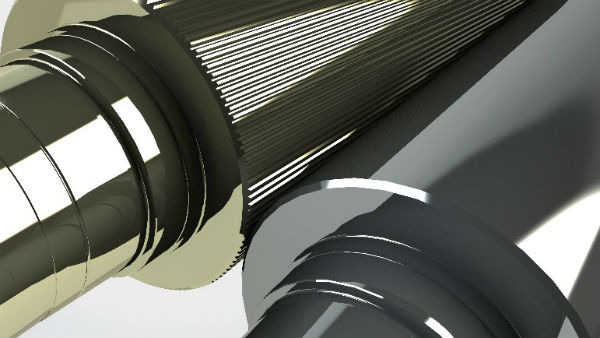

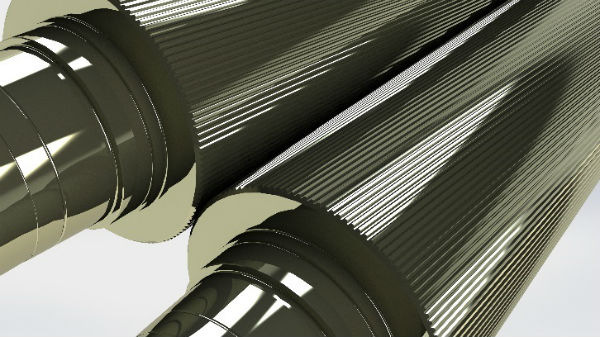

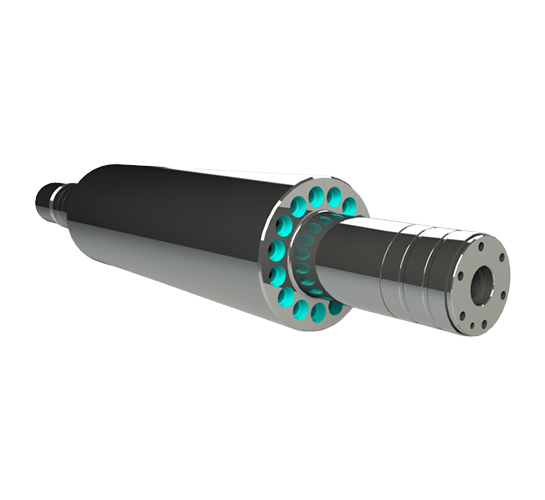

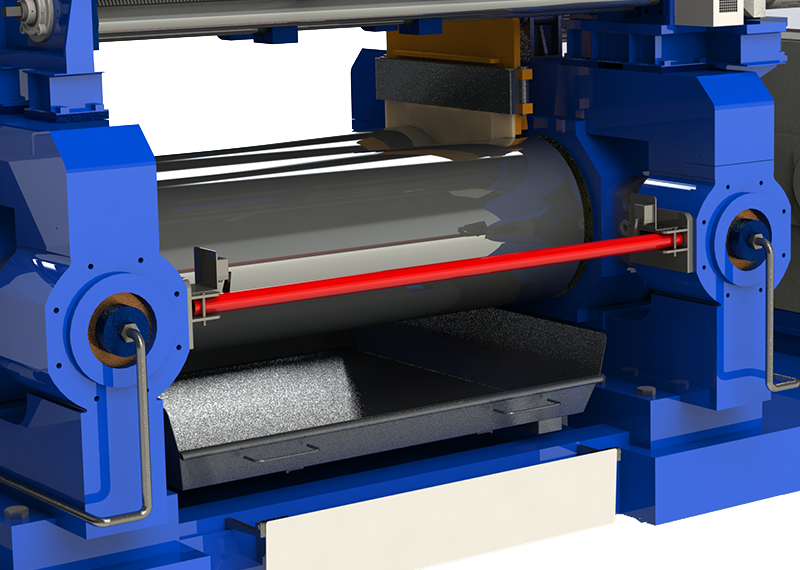

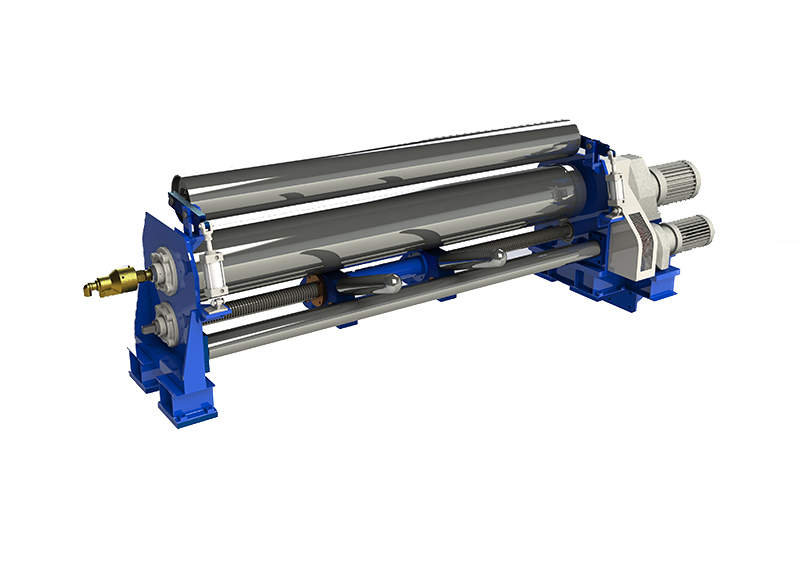

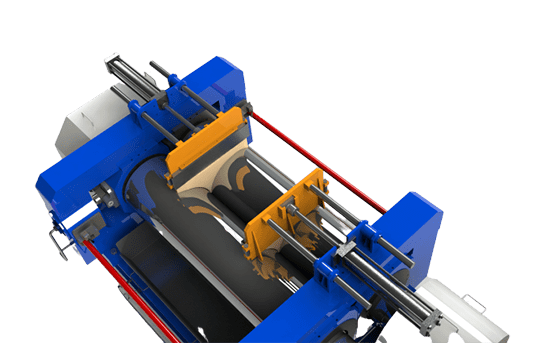

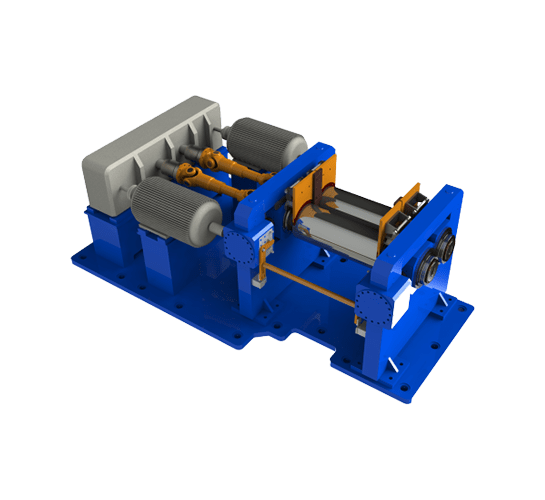

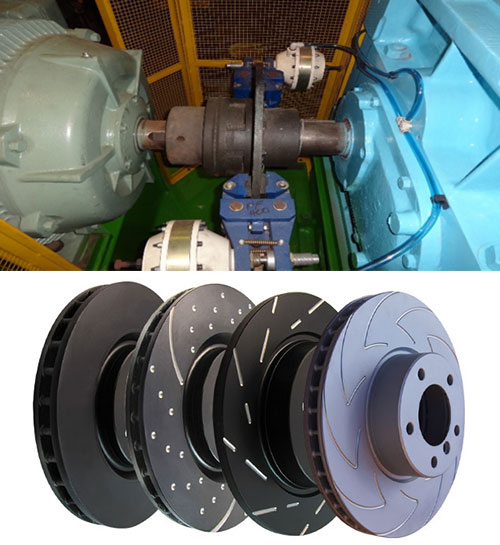

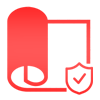

BM series mixing mills are robust and are capable of processing various types of material like Rubber, Polymer, Plastic, off speck rubbers etc. Our mixing mills are popular for it’s trouble free operations and longer life. For example our mills are running for more than 30 years. We offer a wide range of sizes & variants. Single beam base structure makes the mill silent and vibration free. Disc brakes are provided for instant stoppage of rolls during emergency. Mills are available in two options which are: fixed friction and variable friction.

Variants Of BM Series Mills: